Bill Gibbs, prezident firmy Gibbs and Associates, která jako divize společnosti Cimatron software GibbsCAM vyvíjí, pochválil výsledky svých programátorů za výrazný pokrok při rozvoji nové verze tohoto CAM systému.

GibbsCAM 2011, představený počátkem července, doznal pokroku zejména v těchto oblastech:

- Rozpoznávání prvků umožňuje barevně rozlišit typy geometrických elementů a pomáhá určovat, jakým způsobem je GibbsCAM načte. Pokud tyto prvky obsahují uživatelské atributy, dokáže je program v souboru dílu zachovat.

- Definování děr je usnadněno díky automatickému průvodci, který umožňuje uchovávat uživatelská nastavení a využívat je opětovně. Náročná manuální práce při definování vlastností děr se tak omezuje na pár kliknutí myši.

- V oblasti pětiokého obrábění byly přidány nové vlastnosti vrtacích cyklů, konverze nástrojových drah atd. Pomůcka Operation Modifier umožňuje převádět dráhy nástroje z 2,5 a 3 do 5 os, díky čemuž je možné používat kratší nástroje a dosahovat hladších pracovních cest.

(Zdroj: Tisková zpráva)

GibbsCAM 2011 Released with Extensive New Enhancements and Improvements

Includes New Features for Automatic Feature Recognition & Preservation, Hole-Making Automation, and 5-Axis Machining

Moorpark, CA – July 11, 2011

Gibbs and Associates, developer of GibbsCAM software for programming CNC machine tools and a Cimatron company, today announced that it has released GibbsCAM 2011, with dozens of enhancements to make NC programming easier and faster.

“I am very pleased with the result of our development effort in the past year,” said Bill Gibbs, founder and president of Gibbs and Associates. “The 2011 release delivers many significant new features to improve efficiency in programming and machining, all while retaining the ease of use for which GibbsCAM is known. Across the product line, users will find new tools to make their jobs easier and their work more productive.”

GibbsCAM 2011 released July 8, 2011. Among the multiple additions and enhancements within the 2011 release, are the following:

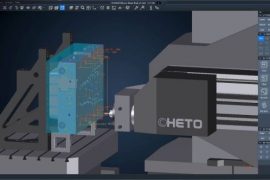

Enhanced Feature and Color Recognition and Preservation – To optimize efficiency and throughput, new tagging capabilities, combined with automatic feature recognition (AFR), allow users to control how GibbsCAM imports CAD models and manages part features and attributes. Color Modes were added to extend tagging and selection criteria of geometric elements – geometry, faces, surfaces and solids. When a part contains user-defined features, or elements tagged with a color attribute, users can switch among Color Modes to distinguish, select or isolate features or elements for manipulation, copying or machining.

As a result of these enhancements, upon opening CAD models, GibbsCAM can read attributes, then recognize and preserve them as attributes in the GibbsCAM part file. Colors are preserved as CAD colors in the part file, and hole features in the model are recognizable and usable as hole features within GibbsCAM hole operations.

Hole Making Capabilities for selecting, organizing, recognizing and drilling holes have been broadly enhanced. Hole Manager, a productivity tool within GibbsCAM, now includes a new Auto Wizard, which allows users to store default settings for reuse, quickly and easily, at any time. Using AFR, holes (and entities that resemble holes) are selectable by part face, set of faces, a hole’s interior faces, or by coordinate system to which a hole feature is aligned. This streamlining enables users to automatically recognize and program hundreds of holes with as few as three mouse clicks, greatly simplifying and speeding up hole-making operations. Also, GibbsCAM now includes support for the full range of SolidWorks hole features.

Custom drill cycle options were added and, to reduce traverse and cycle time in drill cycles, a new check box enables reverse-order drilling.

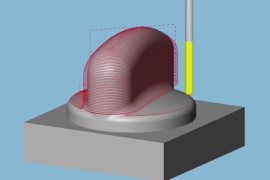

5-Axis Enhancements include various new drill cycle options, toolpath conversion, toolpath smoothing and additional machining styles. The new hole making features make programming drill cycles at off-axis orientations very easy and extremely fast. Programmers can choose drill, variable peck, tap and custom drill cycles.

A new Operation Modifier enables the conversion of 2.5- and 3-axis toolpaths for 5-axis machining, which allows use of shorter tools to achieve smoother toolpaths through tool-axis rotation when the work piece or tooling interferes with the tool holder.

Toolpath smoothing methods have been implemented for all types of geometry, both STL (triangle mesh) and traditional surface geometry, to improve both tilt and rotary toolpath smoothness.

Swarf cutting can now be specified two ways. Users can drive the tool using a) upper and lower curves, with or without a drive surface, or b) a parallel-to-curve strategy with tool-axis rotation. Also new is a 5-axis trimming strategy that uses wireframe geometry.

Support for B-axis (tilting live tooling) was added to enable programming 5-axis milling with Y-axis offsets on lathes and multi-task machines equipped with a live-tooling B-axis.

For more information about GibbsCAM and GibbsCAM MTM, or to locate your local GibbsCAM Reseller, go to www.GibbsCAM.com, call 1-800-654-9399, or email sales@GibbsCAM.com.

About Gibbs and Associates and GibbsCAM

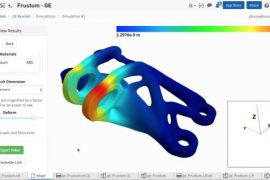

For over twenty-five years, Gibbs and Associates has been a leader in providing cutting edge CAD/CAM technology, while maintaining its signature ease-of-use and productivity. Powerfully Simple, Simply Powerful is the guiding philosophy at Gibbs. Gibbs believes in empowering the NC programmer, machinist, and manufacturing engineer, not eliminating them. Gibbs’ goal is to introduce manufacturers to new technologies and new ways of working that makes their machining easier and their businesses more profitable. To achieve this goal, Gibbs creates tools that are naturally intuitive, graphically interactive, extremely visual, associative, and just plain enjoyable to use. Gibbs provides a total quality solution with the service and support that successful customers require.The current GibbsCAM product line supports 2- through 5-axis milling, turning, mill/turning, multi-task simultaneous machining and wire-EDM. GibbsCAM also provides fully integrated manufacturing modeling capabilities that include 2D, 2.5D, 3D wireframe, surface, and solid modeling. GibbsCAM is Compatible with Windows 7 and Certified for Windows Vista. GibbsCAM’s data exchange capabilities are able to access the broadest range of native and industry standard CAD data formats. GibbsCAM is certified under the Autodesk Inventor Certified Program, is a Siemens Solution Partner Program-PLM for Solid Edge product, and is a SolidWorks Certified CAM Product. GibbsCAM is either offered or endorsed by a number of leading worldwide control and machine tool manufacturers, including GE Fanuc, Infimatic, Siemens, Doosan Infracore, Haas, Index, MAG Fadal, Mazak, Mitsubishi, Mori Seiki, and Tornos. Gibbs and Associates distributes its products worldwide through a network of international Resellers.

In January 2008, Gibbs and Associates merged with Cimatron Ltd., and is now operating as a wholly owned subsidiary. For more information about Gibbs and Associates and its CAM software packages, visit its web site (www.GibbsCAM.com) or call 1-800-654-9399 (outside of North America, call +1-805-523-0004).